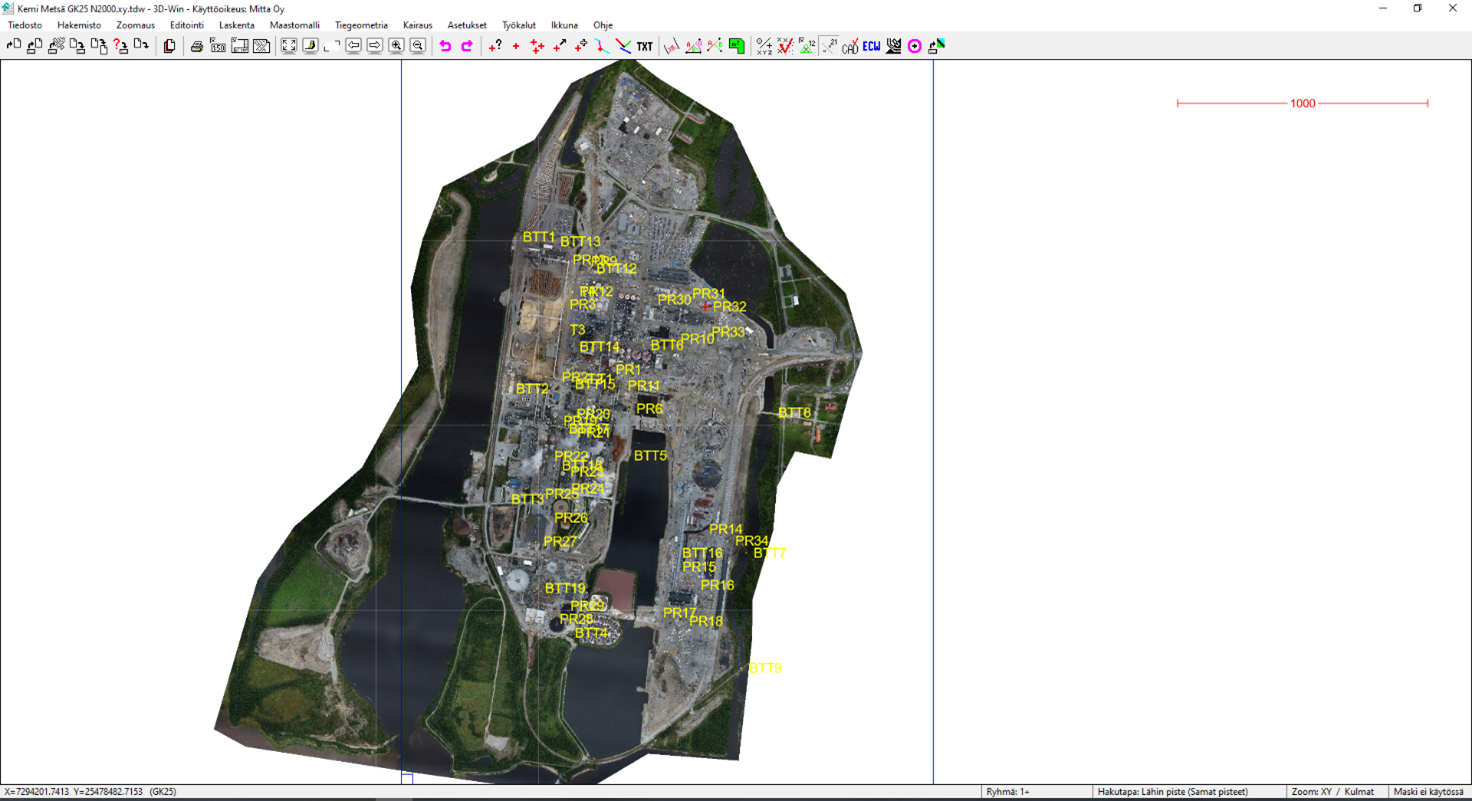

Inspection measurements for the Kemi bioproduct mill project

Thanks to Mitta’s expertise and ample resources, Metsä Group selected Mitta Oy to conduct inspecting measurements of the bioproduct mill.

When completed, Metsä Group’s Kemi bioproduct mill will be the most efficient wood processing plant in the Northern Hemisphere. This is the largest investment in the history of the Finnish forest industry, valued at EUR 2.02 billion. The environmental friendly, energy- and material-efficient plant operates completely without fossil fuels.

The bioproduct mill will be started up in the third quarter of 2023. The bioproduct mill will produce 1.5 million tonnes of Metsä-branded softwood and birch pulp per year as raw material for paperboard, tissue and printing paper, and special products, Metsä Group is announcing its bioproduct mill project.

It is easy to start collaborating with a well-known company

“Mitta Oy is a well-known operator in its field of expertise, and we have cooperated with Mitta on several projects. They performed similar tasks e.g. In the Äänekoski bioproduct mill project,” says Eelon Lappalainen, Construction Manager of the Kemi project.

“As part of the bioproduct mill project, we have engaged Mitta to design fixed metering point networks, allocate metering points to suppliers and contractors, perform on-site measurements and drone photography on behalf of the client, and provide quantity measurement services related to laser scanning,” he further elaborates.

Jouni Impiö, the Senior Surveying Supervisor, who brings 21 years of experience at Mitta and a total of 40 years in the field of measurement work, describes the project as being smooth from the start.

“The project itself began in 2020 with the first measurements at the Kemi mill area. At that time, preliminary measurements were carried out for designers. I joined the project in April 2021.”

Getting to know the staff was also a pleasure for Impiö, who says that it is nice to work when you have skilled friends with you.

The monitoring measurement group consisted of four people; Jouni Impiö (m.sc. tech) Supervisor of the control group, fieldwork, Janne Granholm (mmins) responsible for mass balance, fieldwork, Kari-Pekka Raappana (mmtekn) mass balance, fieldwork and Markku Palosaari (mmins/rak – and combined) mass balance, fieldwork.

A similar project was previously undertaken by Mitta for the Äänekoski bioproduct mill, demonstrating that the expertise and resources of Mitta’s personnel are adequate for executing a project of this magnitude, as affirmed by Lappalainen.

“The biggest factor influencing the purchase decision is the previous successful customer experience of the Äänekoski project.”

On Mitta’s side, the goal of the bioproduct mill project was to make everything run “silky smooth”.

“Our utmost goal was to provide the best possible service to Metsä Fibre. Adhering to the timeline was a top priority, and we consistently prioritize and manage service requests in an efficient and logical order,” Impiö explains.

Mitta Oy provided Metsä Group with a measurement base, mass calculation monitoring and up-to-date aerial photography

A measurement basis was laid for the Kemi bioproduct mill construction site:

- On-site, there are established fixed reference points that serve as the foundation. The point network has been enhanced and expanded specifically within the factory area, enabling contractors to accurately measure and position the buildings.

- For the project, the geodetic backbone network was surveyed using GPS/GNSS technology, and the calculations were conducted using PNS network leveling methodology. Additionally, the points underwent precision leveling to determine their respective heights.

There were 9 frame points. These points were in the GK25 system and the height in the N2000 system. In addition to this, a factory coordinate system was created on the site, which was rectangular to the buildings.

In a large factory area, distances are long

“The distances between different sites can span around 400 to 500 meters, with conveyors running between them. In a simplified manner, it can be said that precise alignment of the conveyors is of utmost importance,” describes Impiö.

The reference points have been diligently maintained, and to gather additional data, weekly aerial photography of the factory area is conducted, subject to favorable weather conditions.

“Up-to-date aerial photography is used, for example, as a design aid. We are also able to monitor mass counting, such as how much land is still needed where. Plans can be placed on top of aerial photographs: How buildings and cables, etc. rank. This avoids unnecessary pipe and cable cuts.”

On the monitoring side, initial data points have been established within the buildings to assist installers in accurately placing equipment at the designated locations. Periodic inspection measurements are conducted to ensure that the structures align with the planned specifications.

Eelon Lappalainen describes the benefits of Mitta in the project:

“Without the services provided by Mitta, such modern projects with high demands on measurement accuracy are impossible to implement. During the project, Mitta was used to solve many practical problems, such as filling gaps in suppliers’ surveying capacity and expertise.”

According to Impiö, the cooperation has also been flexible. As the plans have progressed and in case of possible changes, additional measurements have been carried out.

“If problems have arisen, we check that the structures are in the right places and that the designers can solve the problem.”

Measurement accuracies are a criterion on construction sites: In this project, measurement is aided by e.g. GK 25 plane coordinate, N2000 height system and rectangular factory coordinate system.

Metsä Fibre’s internal Metsäappi app and close communication contribute to the success of the project

“At this point, I can say that everything has gone well in the project. It has been possible to release staff on schedule. Even though plans change over time in such large projects, I can say that we have progressed as we should,” Impiö says.

Metsä Group has also felt that the whole process goes very well:

Communication and collaboration have been excellent, maintaining a professional approach while also enjoying a positive on-site humor. We are extremely satisfied with Mitta’s overall performance as well. We have achieved superior results in terms of the coordinate system compared to previous projects, and there have been no measurement errors,” Lappalainen states. Internal communication and project monitoring within Mitta have also been seamless:

“The communication within our team has been highly effective. We utilize the Metsäappi application, which provides updates and information regarding the project. Additionally, email notifications are sent to ensure timely communication.”

“Mitta can definitely be recommended for similar projects”

Eelon Lappalainen says nothing but good things about the project with Mitta:

The greatest strength of our collaboration lies in the presence of skilled and professional resources who foster seamless cooperation and effortless communication. The team at Mitta showcases exceptional expertise and professionalism, making it easy to establish a productive working relationship.”

“I would definitely recommend Mitta to others,” he concludes.